High Precision Swiss Screw Machining / CNC Machining & Grinding Services

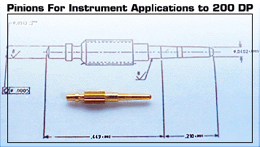

For specialized, high precision parts where tight tolerances are important, IFG Instruments provides CNC Swiss screw machining services as well as standard CNC machining and grinding. Swiss screw machining is ideal for smaller scale parts where several machining operations may be required, and we are equipped to work with parts with diameters from 0.20 mm to 16 mm (0.008” to 0.640”), up to 180 mm (7.0”) long. For our standard (non-Swiss) CNC grinding and machining operations, we can handle parts from 0.20 mm to 30mm (0.008” to 1.20”) in diameter and a 180 mm (7.0”) length.Our Swiss screw machines feature a collet and guide bushing system that keeps parts vibration-free as they are being worked, allowing us to achieve a fine level of detail in our operations. Our machining methods also allow us work with conventional as well as a wide range of exotic metals, including Nivapoint. Swiss and conventionally machined products are used in instruments and apparatus such as water pivots, pinion applications, and helical or spur gears with fine pitches.

Corepoint Pivots Information & Specifications (PDF 523KB)

Precision Screw Machining Highlights

|

Applications |

Water Pivots Pinion Applications Helical or spur gears with fine pitches |

|

Materials |

All Ferrous Nonferrous Aluminum Alloys 300 and 400 Series Stainless Steel |

|

Exotic Materials |

Nivapoint Corepoint Other Exotics |

|

Tolerances |

0.005mm |

|

Sizes for CNC Machining and Grinding |

ø 0.20 to 30.00 mm (.008 to 1.200″) Length to 180 mm (7.00″) |

|

Sizes for Swiss + Quality Screw Machine Parts for Instruments & Apparatus |

ø 0.20 to 16.00 mm (.008 to .640″) Length to 180 mm (7.00″) |

|

Quality Certifications |

Modern equipment and methods enable us to become your Certified Supplier, saving time and money. ISO 9001:2000 certified |

|

Burrfree |

Your parts can be de-burred internally as well as externally; by our internal Tumbling glass/sand bead system. |

|

CNC Length |

up to 100 mm |

|

Swiss Screw Machine Diameter |

1 mm to 10 mm |

|

Swiss Screw Machine Length |

up to 70 mm |

Carepoint Products

|

Diameter |

0.1 mm to 1.6 mm | ||||

|

Length |

1.2 mm to 70 mm | ||||

|

Composition |

|

||||

|

Modules of Elasticity |

|

||||

|

Modules of Shear |

|

||||

|

Elastic Limit |

|

||||

|

Tensile Strength |

|

||||

|

Hardness Max. |

770 – 820 Vickers | ||||

|

Specific Gravity |

8.2 g/cm3 | ||||

|

Specific Resistance |

1.0 x 10-4 Ω cm | ||||

|

Temperature Coefficient of Resistance |

0.23 x 10-3 per °C | ||||

|

Linear Expansion |

13 x 10-6 per °C | ||||

|

Magnetic Permeability |

1.001 | ||||

|

Corepoint strengths – almost constant in the temperature range |

-58 °F to 842 °F (-50 °C to 450 °C) |

||||

|

Welding & Brazing |

Use Castolin 197 with binder 159 A for brazing. For an absolutely corrosinresistant brazed joint precious metal brazing solders with melting points around 1100 °C will give best results. | ||||

|

Dimensions |

Corepoint – parts are being manufactured up to a maximum diameter of 1.5 mm (.059″). |